Sustainability is not just a trend. It is a must if we want our children and future generations to inherit a healthy planet on which to live. Every societal actor has a responsibility to bear. In this talk, Bruno will give insight as to how a major manufacturer of consumer goods deals with this issue.

Bruno Vermoesen began as an engineer working for BSH Home Appliances in 1995 in the marketing department. For the past 20 years he has been active as a lobbyist in the field of European legislation, focusing on energy efficiency, performance, waste and the circular economy. Bruno is also the President of Recupel, the Belgian takeback system for waste (electrical and electronic appliances), and a Board Member of the Dutch takeback system Wecycle. In addition to these tasks, he is also the Sustainability Officer for the BSH sales area of Western Europe.

On February 13, ISG members had an opportunity to hear a very enlightening lecture by Bruno Vermoesen. Bruno is an engineer who works for BSH Home appliances. BSH is part of Germany’s Bosch Group with headquarters in Stuttgart.

The parent company Bosch was created in 1886 and now is a major manufacturer of consumer goods with over 300,000 employees and annual sales of 51 billion euros. The company has factories in 60 countries and its products are sold in 150 countries. This makes Bosch a leading global producer of home appliances. Bosch began by making parts for cars. In 1925 they installed their first conveyor belt. From 1929 the company changed its mission and began producing consumer goods. For 20 years, Bruno Vermoesen was the President of BHS's Take Back System dealing with recycling.

Consumer goods are used daily, and the subject of this lecture concerns us all, so the audience was attentive to the ideas set out by the speaker. He presented the issues which the company pays attention to which are sustainability and the economic and social environment. (Economic meaning supporting long term economic growth without damaging the environment.)

BHS concentrates on three goals: decent work conditions, responsible consumption and production, and climate action. Putting 60 million of their products on the market annually, gives the company a sense of responsibility.

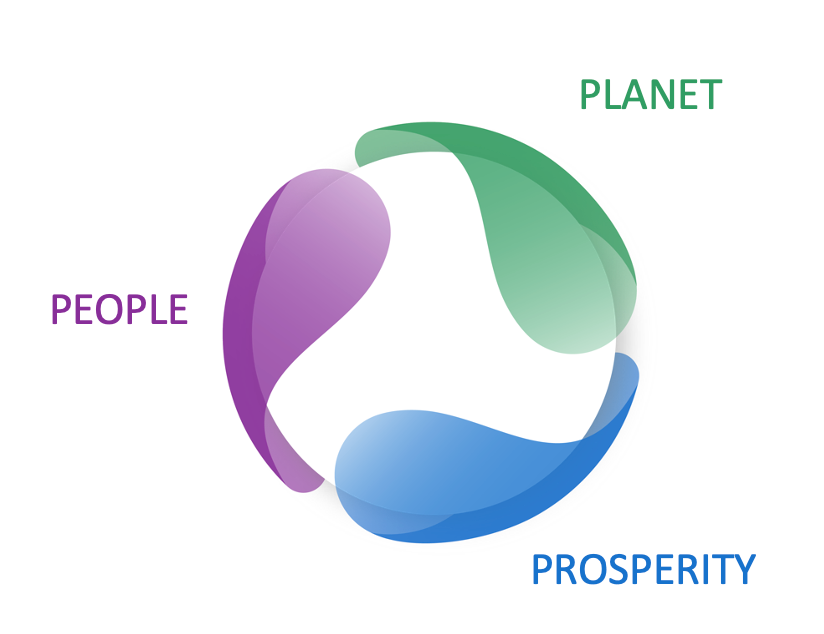

The speaker made a circle on the screen, indicating three points at the circumference: planet, people, property. He said: “We save natural resources, or we study the impact of our productivity. We are focusing on the resources. We avoid harmful substances. We use the same standards in every country of the world and adhere to the same safety requirements. We want to achieve zero accidents in our factories. We use the same products.” He indicated four issues which are involved in a clean work environment. The main thing is CO2 and how to cut it or getto lower levels. In 2020 the company realized the goal of being CO2 neutral. They distributed the sources of CO2 by scopes ranking from one to four.

Scope 1 Burning fossils leads to direct carbon emission.

Scope 2 Indirect carbon emission like using electricity. BHS have reduced emissions by using several methods, such as installing special bulbs, generating their own green energy by installing solar panels on the roofs of their buildings.

Scope 3 They purchase green energy.

Scope 4 If BSH produces CO2, it is compensated for by different methods like planting trees. If they nevertheless produce CO2, they try to compensate for it by different methods like planting trees. The company hopes that by 2030 it will be able to cut 15% of CO2 in their products.

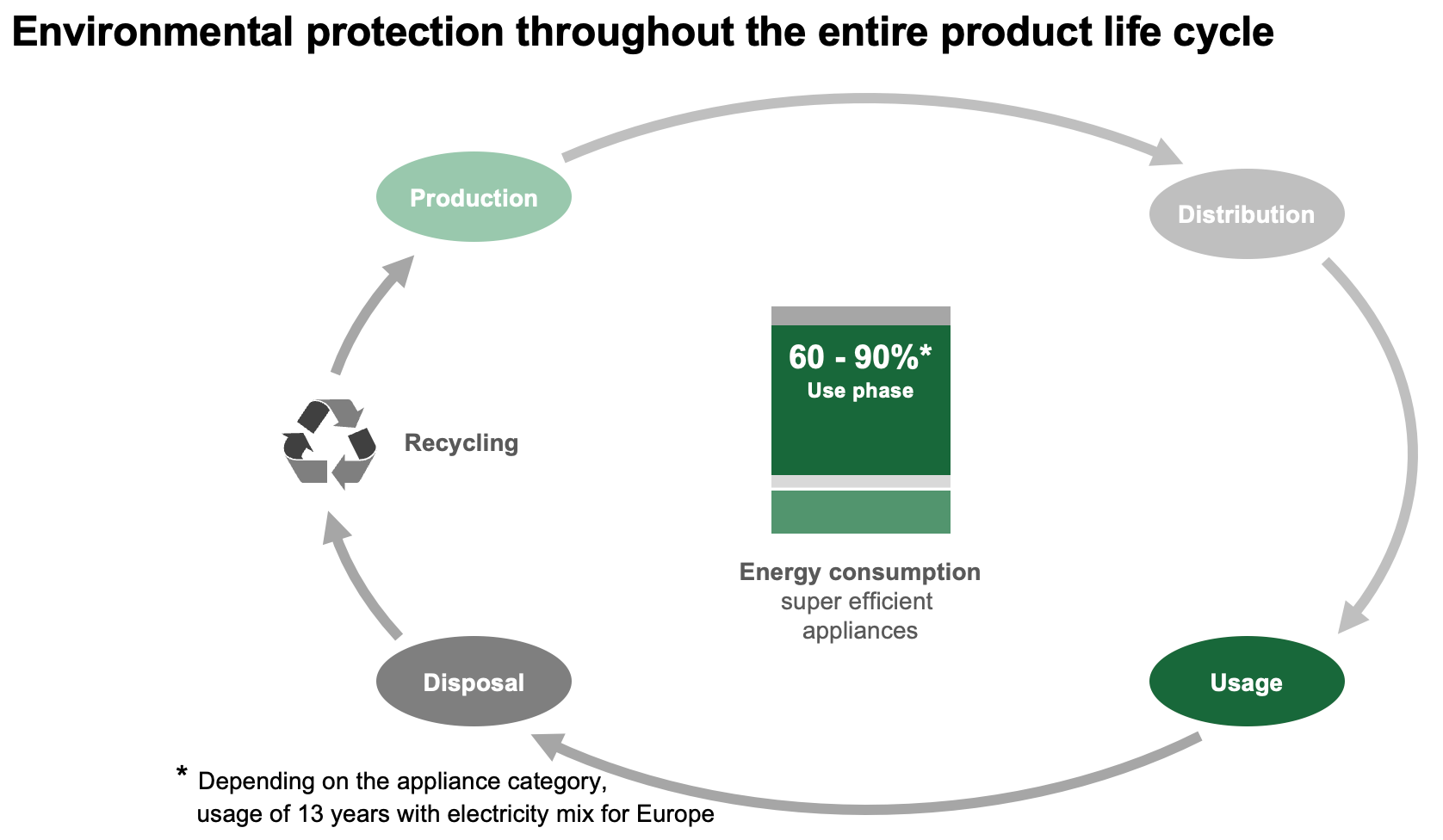

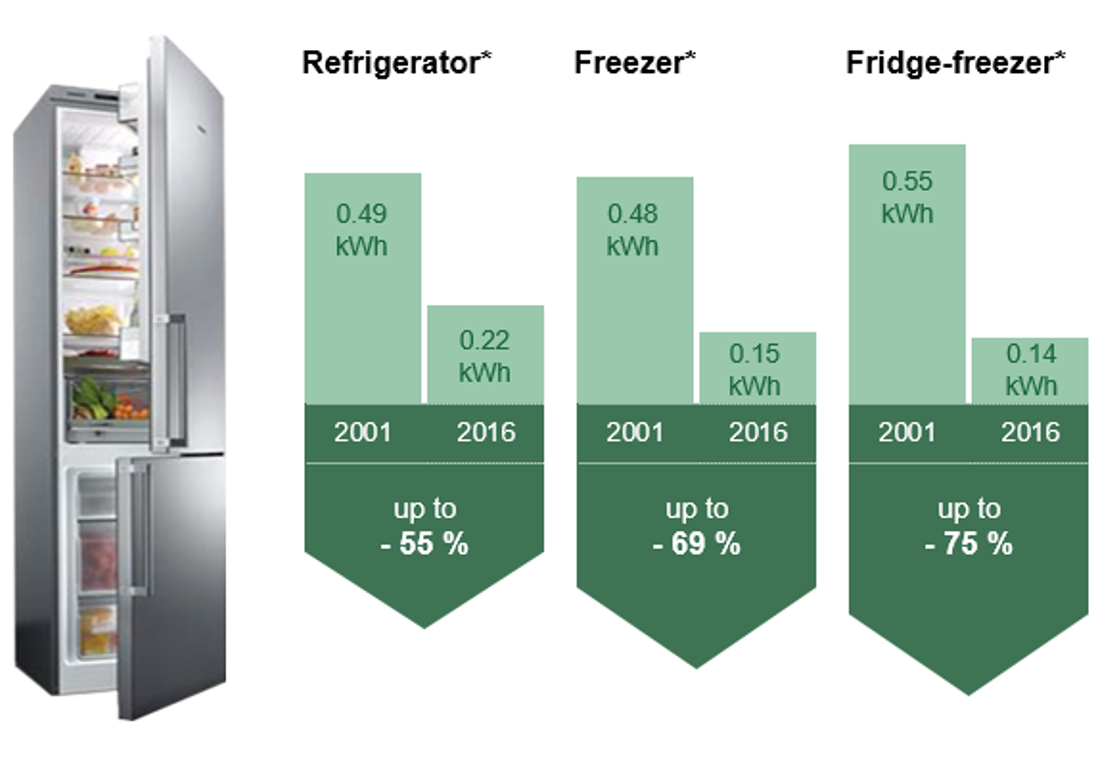

While transportation is a big problem, the use of the company's products in the home environment is the most wasteful phase from the point of view of saving energy. It accounts for between 60-90 % of energy use. It is the most important part of the research cycle to reduce the energy consumption. From 2000 to 2015, the company reduced energy consumption of their stoves by 43%. From 2001 to 2015, they reduced 55% of the energy used by refrigerators and 68% in washing machines, while also reducing water consumption by 57%.

But the company cannot rest on its laurels. It has to improve, though the speaker admitted that it will be more difficult to do so going forward unless new technology comes to the market. Steel is a very important resource from the point of view of energy consumption. To produce it demands a lot of energy the company tries to use steel coming from green energy using oxygen, not from coal burning. The company does not forget about their employees’ situation. They also have goals, among them to achieve diversity of the team, for example, they want to reach 30% of women in their staff. The company is attentive to issues of health, contribution to society, diversity, equality and inclusivity. Bruno offered his own case as an example of inclusivity. His father worked for the company, now he himself works for the same company for 29 years. And he assured us that he is not unique. “Many people in our company like me work here for many years.”

The company constantly looks for new innovations or new initiatives.

Bruno explained what he meant: ”We develop appliances which can work without being connected to gas or electricity. Take for example the refrigerator”. He showed us a picture of a Blue Box, a refrigerator that works on water. “They are used in Kenya”. BHS also developed a solution to heat the stove without gas or electricity. These solutions are cheap and needed for poorer countries.

Any company needs to grow, and this company as well, meaning that they want to produce more goods, but they hope to reduce their environmental impact. One possibility is to rent the appliances. In this case the company is responsible for their service life and condition. The cost of maintenance would be on the company, not on the consumers.

Bruno explained the concept of Circular Economy. “Circle One: Produce – repair – recycle – refurbish. It is classical. But we won’t use this classic system. We want to do the next one: Circle Two: reuse or share or lease.” The speaker again showed a circle on the screen and called it circular economy. From number One the arrow moves to number Two. “We want our goods to be repaired”, he added.

There is now a new business model such as sharing. “We want to reduce the use of raw materials, use them less and less or use different materials. For example, we try to avoid using rare plastics or critical raw materials. This is our goal. Also, we want to prolong reliability and reparability of our products.”

In Belgium there are 80 company engineers working to repair Bosch products. Most of the company’s appliances serve for 15 years. They allow other companies to repair their products. At the same time, they want to avoid recycling and collaborate with other companies, offering them their products. For the company recycling is the last resort. Everything, and not only metal has to be saved and re-enter useful life. Most recycling products are reused in the car industry. The company wants to put standards on secondary raw materials, but for this they have to find a proper business model.

The speaker addressed the audience: “You are also a player/participant in this scheme. If you want to get rid of your old refrigerator, find a place where they will reuse everything, and not only the metal”.

Recycling is part of the circular economy which helps to improve life.

Bruno presented three systems: 1 Blue Movement, 2 Papillon project and 3 WeWash. The equipment is rented. The system is intended for poorer people. People pay a monthly rent; they don’t need to purchase.

The equipment is shared like a shared washer in dormitories or students homes. This system works in many countries. These are the business models.

“These three systems stimulate the company, because we get the machines back and we have to do something with them. We have people who watch what we are doing and promote our initiatives. We want to have a positive impact on people and society.”